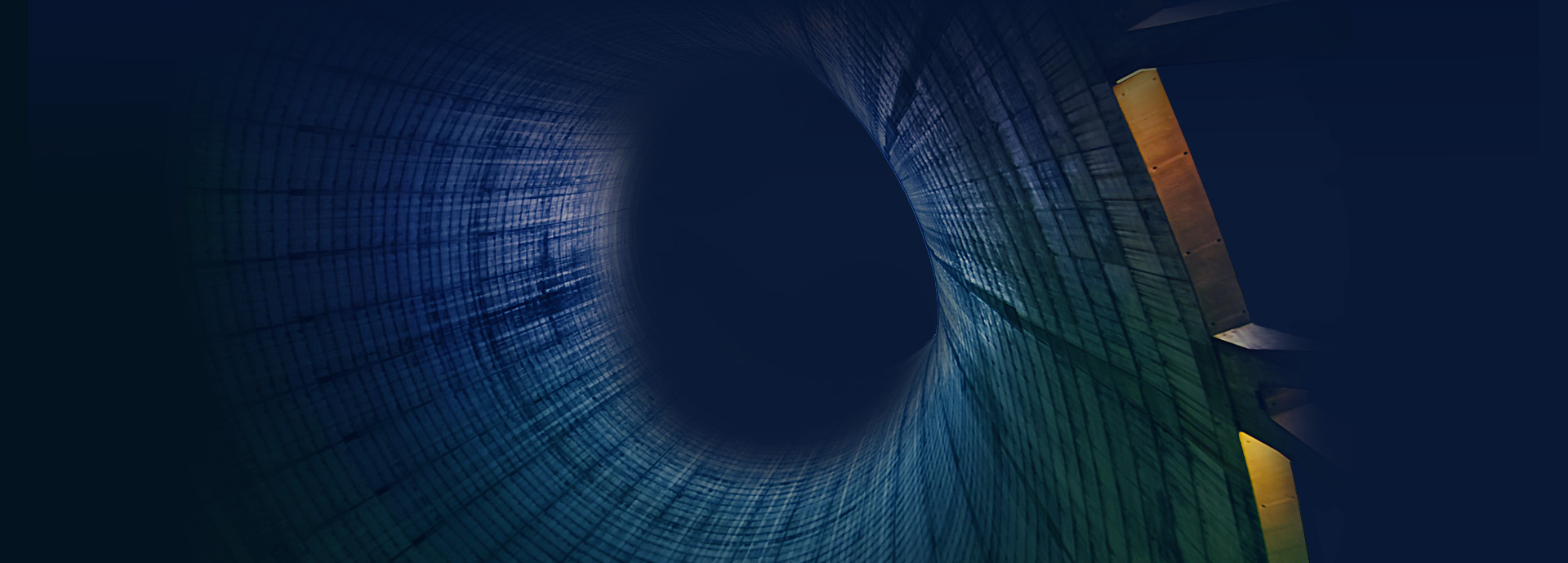

Cooling fills

Application

Cooling tower fills are used as cooling media into crossflow and counterflow cooling towers with natural and forced draft, where fill type and number of layers are dependent on requirements:

- Total cooling performace and water distribution.

- Size and type of the cooling tower.

- Water quality and the risk of clogging of the fill.

Characteristics and material properties

- The various types of cooling tower fills differ in design, the number and size of distribution channels, as required for maximum cooling performace and environmental influences.

- There are 2 types of material availlable in case of need high impact resistance for areas with extremely low temperatures:

standard - impact resistance up to -30°C

extreme - impact resistance up to -50°C

- Used material - PVC - is resistant to weather and chemical degradation by acids, alkalis, greases and biological attack.

- PVC conforms the excelent fire rating due to its self-extinguishing nature.

Assembling a cooling tower fill block

Thermoformed cooling tower fills are assembled by using the connecting elements or thermal welding.

- The method for assembling blocks allows installation right on construction site of the cooling tower and saves transportation costs.

-

Number of connection points ensures sufficient rigidity and strength of the block.

- Assembly into block is done without use of any adhesives and meets all the requirements in relation to the environment.